Evaluating color fastness to washing is a crucial process in the textile industry, ensuring that fabrics maintain their color integrity after repeated laundering. This evaluation is essential for manufacturers, retailers, and consumers alike, as it directly impacts the quality and longevity of textile products. This article will delve into the methodologies, standards, and best practices for assessing color fastness to washing, providing a comprehensive guide for those involved in textile testing.

Understanding Color Fastness to Washing

Colorfastness to washing refers to the ability of a dyed or printed fabric to retain its color when subjected to laundering processes. It measures two main aspects:

- Color Change: The degree to which the original color of the fabric fades or alters after washing.

- Staining: The extent of color transfer from the test fabric to adjacent fabrics during the washing process.

These evaluations are critical for various textile applications, particularly in clothing, home textiles, and industrial fabrics, where frequent washing is expected.

Importance of Evaluating Color Fastness

The significance of evaluating color fastness cannot be overstated:

- Consumer Satisfaction: Fabrics that retain their color after washing are more likely to meet consumer expectations for quality and durability.

- Brand Reputation: High-quality textiles contribute positively to a brand’s image, while poor color fastness can lead to customer complaints and returns.

- Regulatory Compliance: Many markets have specific standards for textile quality, including color fastness. Meeting these standards is essential for market access.

Color Fastness to Washing Test Method

The most widely recognized method for testing color fastness to washing is outlined in ISO 105 C06. This method simulates domestic or commercial washing conditions and involves several key steps:

1. Sample Preparation

- Cut fabric samples into standardized sizes (typically 100 mm x 40 mm).

- Attach the test samples to specified adjacent fabrics (multifiber fabric) using sewing techniques along one edge.

2. Test Setup

- Prepare a detergent solution according to standard specifications (e.g., using sodium perborate and ECE phosphate).

- Set up the washing fastness tester (such as a Rotawash or Gyrowash) with appropriate settings for temperature (commonly 40°C or 60°C) and duration (usually around 30 minutes).

3. Washing Process

- Place the prepared samples into the detergent solution within the tester.

- Subject the samples to mechanical agitation that mimics real-world washing conditions.

4. Rinsing and Drying

- After the wash cycle is complete, rinse the samples thoroughly with hot water.

- Squeeze out excess water and dry the samples at controlled temperatures not exceeding 60°C.

5. Evaluation of Results

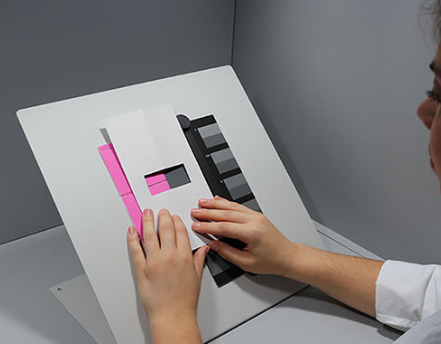

After drying, evaluate the samples for color change and staining:

- Use grey scales or digital instruments to assess color change on a scale from 1 (poor) to 5 (excellent).

- Examine any staining on adjacent fabrics using similar scales.

Testing Standards

Several international standards govern color fastness testing, including:

- ISO 105 C06: The primary standard for evaluating wash fastness.

- AATCC 61: A method specific for assessing colorfastness in laundering textiles.

- GB/T 3921: The Chinese standard that aligns closely with ISO methods.

Each standard specifies different conditions regarding temperature, detergent concentration, and mechanical action, allowing for flexibility based on testing requirements.

Factors Influencing Color Fastness Evaluation

Several factors can affect the results of color fastness testing:

- Dye Type: Different dyes have varying affinities for fibers; reactive dyes generally provide better wash fastness than direct dyes.

- Fabric Composition: Natural fibers like cotton may behave differently than synthetic fibers like polyester under washing conditions.

- Washing Conditions: Variations in temperature, detergent type, and agitation can significantly impact results.

- Sample Preparation: Consistency in sample size and attachment methods is crucial for reliable results.

Best Practices for Accurate Evaluation

To ensure accurate evaluation of color fastness to washing, consider these best practices:

- Standardize Testing Conditions: Always use standardized methods and conditions as outlined in relevant testing standards.

- Regular Calibration of Equipment: Ensure that testing equipment is regularly calibrated and maintained for consistent performance.

- Conduct Multiple Tests: Running multiple tests can help identify variations in results due to different factors.

- Document Results Thoroughly: Maintain detailed records of all tests conducted, including sample details, conditions used, and results obtained.

Interpreting Test Results

Interpreting test results involves understanding what different ratings mean:

- A rating of 4 or higher typically indicates acceptable performance with minimal color change or staining.

- Ratings below 4 may suggest that the fabric is not suitable for its intended use if frequent washing is expected.

Using grey scales provides a visual reference that helps ensure consistency in evaluations across different testers and laboratories.

Conclusion

Evaluating color fastness to washing is an essential process in ensuring textile quality and consumer satisfaction. By following standardized test methods such as ISO 105 C06 and adhering to best practices in sample preparation, testing conditions, and result interpretation, manufacturers can produce high-quality textiles that meet market demands.As consumer expectations continue to rise regarding fabric performance, investing in robust testing protocols will be vital for success in the textile industry. Understanding how to properly evaluate color fastness not only enhances product quality but also helps maintain brand reputation in an increasingly competitive marketplace.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: [email protected]