Table of Contents

- Introduction to Pipeline Maintenance

- Why Pipeline Maintenance Matters

- Common Challenges in Pipeline Maintenance

- Effective Strategies for Maintenance

- Role of Technology in Modern Maintenance

- Future Trends in Pipeline Maintenance

Introduction to Pipeline Maintenance

Gas, water, and oil transportation over long distances relies heavily on pipelines; therefore, regular maintenance is essential for both efficiency and safety. Over time, pipelines can develop issues such as corrosion, blockages, and leaks, leading to costly repairs or environmental risks. Routine inspections and preventive maintenance help detect problems early, ensuring the pipeline remains in good working condition. A well-maintained pipeline reduces the risk of failures and extends its lifespan, making it a reliable part of infrastructure systems.

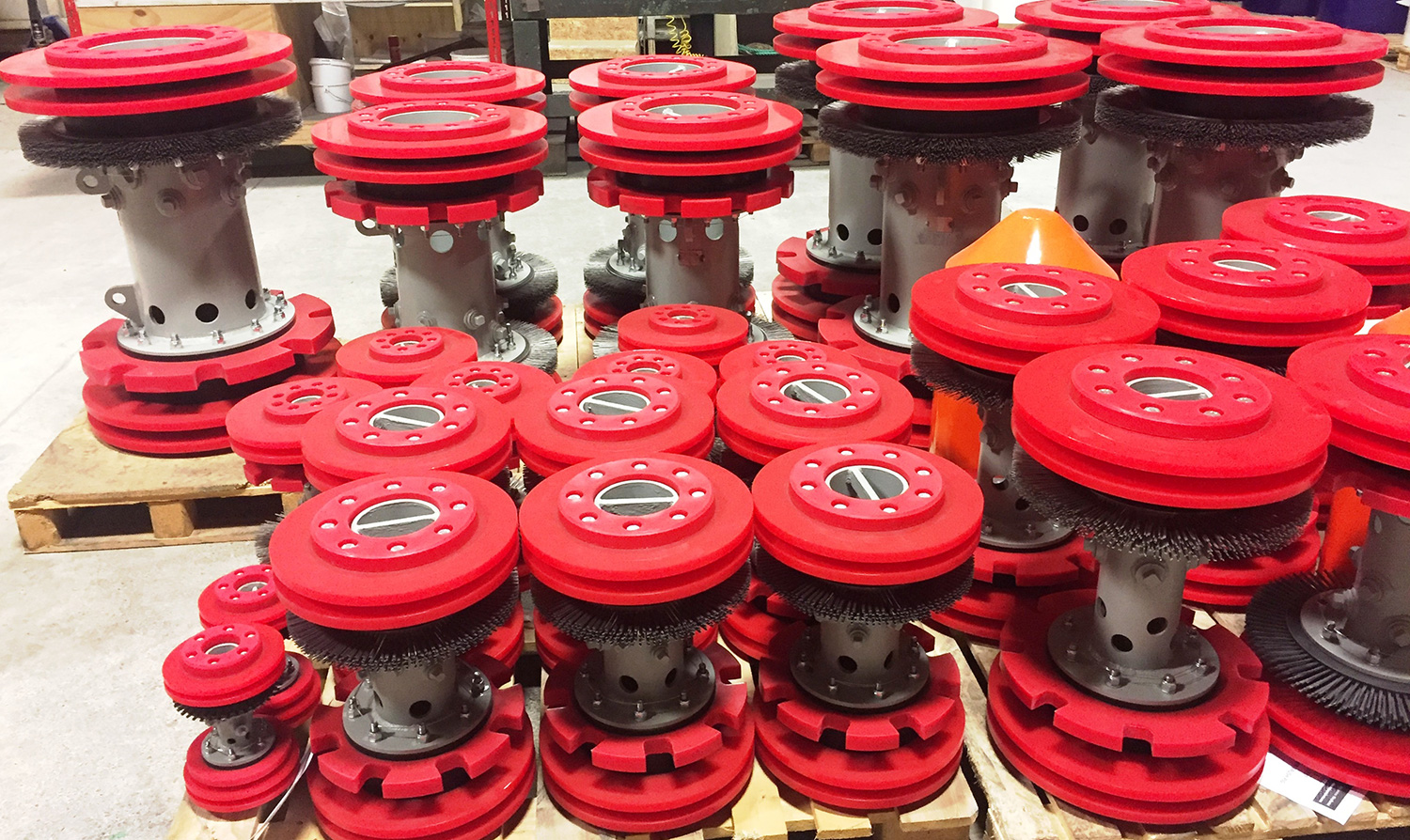

One important method used in pipeline maintenance is pigging equipment, which helps clean and inspect the interior of pipelines. These “pigs” devices travel through the pipeline to remove buildup, check for damage, and improve flow efficiency. Regular use of pigging equipment prevents blockages and reduces wear, helping to maintain smooth operation. Maintenance efforts support the safe and efficient transport of materials by keeping pipelines clear and functioning correctly.

Why Pipeline Maintenance Matters

Pipelines are more than mere transport mechanisms; they symbolically fuel the industrial world. Their maintenance is vital to preventing leaks that can have catastrophic environmental impacts, such as contaminating water sources or harming wildlife habitats. Besides environmental concerns, poorly maintained pipelines can lead to significant operational inefficiencies, causing downtime and financial losses. By ensuring that pipelines function seamlessly, companies can protect their bottom lines and reputations, delivering resources reliably and safely to where they are needed most.

Moreover, routine maintenance activities can help entities comply with various health and safety regulations. Penalties for non-compliance can be steep, and the cost of rectifying an incident post-failure can be exponentially higher than the expense incurred by regular maintenance. Ultimately, effective pipeline maintenance serves as a preventive measure that safeguards commercial interests and environmental integrity alike.

Common Challenges in Pipeline Maintenance

- Corrosion and Material Degradation: As pipelines age, they become prone to corrosion. This chemical process slowly eats away metal, leading to potential breaches. Regular inspection and treatment with anti-corrosive materials are necessary to combat this.

- Remote and Hard-to-Access Locations: Many pipeline systems traverse remote terrains, making regular maintenance checks difficult and expensive. Adverse weather conditions can further complicate these access issues, making it a logistical challenge to maintain a schedule.

- Environmental and Regulatory Compliance: Compliance with industry standards and environmental regulations requires meticulous documentation and continuous monitoring. Striking a balance between operational efficacy and regulatory adherence often involves ongoing audits and adjustments.

Effective Strategies for Maintenance

The foundation of successful pipeline maintenance lies in adopting a proactive approach. This involves scheduling regular inspections and risk assessments to catch potential issues before they escalate. Predictive maintenance, wherein data forecasts potential failures, is a powerful tool. Employing technology that predicts failures can improve reaction times and reduce unnecessary service calls and interventions.

Additionally, integrating cutting-edge ‘smart’ technologies such as advanced sensors and real-time data analytics into maintenance regimes ensures a prompt response to emerging issues, keeping pipelines operating efficiently and safely. This proactive strategy may significantly increase the efficacy of maintenance initiatives when paired with a strong focus on employee training and development.

Role of Technology in Modern Maintenance

Technology has transformed the landscape of pipeline maintenance, offering new tools and methods for managing infrastructure assets. Using drones for aerial inspections has shown immense promise, providing visual data without requiring personnel to enter potentially dangerous locations. Moreover, the importance of the Internet of Things (IoT) cannot be overstated. IoT devices are automated sensors that enable continuous monitoring of pipeline integrity. Real-time data collecting and analysis is now essential for promptly spotting abnormalities that can point to new issues thanks to the Internet of Things capabilities.

Technology continues to push boundaries, with autonomous vehicles and robotic crawlers already in experimental phases to assess and repair pipelines internally. Such innovation points towards a future where human interaction with hazardous jobs might be reduced, further highlighting the importance of technology in paving the path for safe, efficient, and reliable infrastructure management.

Future Trends in Pipeline Maintenance

The technology supporting industries is constantly changing along with them. Looking to the future, artificial intelligence (AI) and machine learning (ML) are poised to enhance pipeline maintenance capabilities significantly. These technologies offer predictive and analytical capabilities far surpassing current methods, allowing for preemptive action to prevent failures before they occur.

Integrating AI into monitoring systems means repairs could be diagnosed and scheduled without human intervention, paving the way for self-regulating and self-healing pipeline systems. This evolution represents a substantial leap forward, promising to reduce operational costs and environmental impact further while boosting pipeline operations’ overall safety and reliability.